M.I.R.A Barrier Crash Test

With not only the ever increasing volume of traffic on the roads, but also the size and weight of modern commercial vehicles, there has been a need to review the quality and suitability of crash barriers throughout the UK.

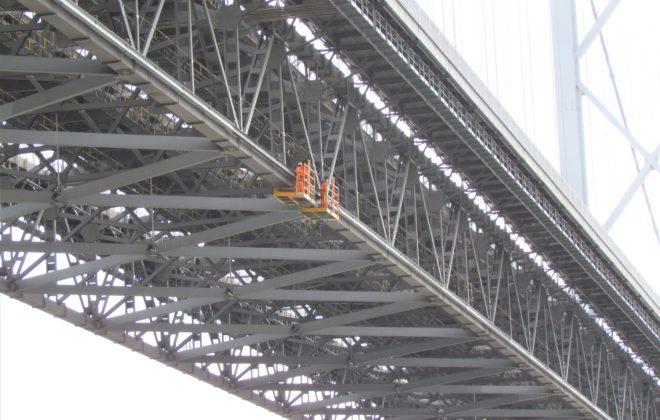

When Millar Callaghan were contracted to replicate the crash barriers on the Forth Road Bridge, the first and most important thing we had to do was confirm the material grade and specifications to which the original barrier was manufactured. This was achieved by removing a one-metre section of the existing rail and replacing it with a new section.

The one-metre section was then sent to a laboratory where it was tested under tensile, shear and compressive loads. With these results, material was sourced that matched that of the 1966 original fabrication. Failure to get an exact match would result in an unrealistic comparison between the results from the test section and that of the original crash barrier.

With the material and construction specifications identified, fabrication jigs were manufactured to ensure consistency and symmetry across new sections. With the new sections completed, the panels were shot blasted and painted to the same highway specification as the bridge structure.

The barriers were then erected at the MIRA test facility at Nuneaton where a test vehicle was crashed at a pre-determined speed and angle to simulate a collision on the bridge. The damaged sections were replaced and further successful tests were then carried out with a selection of vehicles at various speeds.